Un siècle d'histoire et d'innovations

Il y a presque six décennies, Jacques Augros participe à la révolution des bouchons en verre des flacons de parfum avec une innovation majeure, le système PLAST-EMERI, suivi par le système OPERCULE, utilisé par les plus grandes marques.

En 1980 Jacques Bourgine rachète Augros Cosmetic Packaging et sera rejoint en 1991 par son fils Didier.

Jacques et Didier Bourgine insufflent une dynamique de développement sur trois axes :

1. LA GLOBALISATION DES COMPÉTENCES afin de maitriser et couvrir toute la chaine de productions

avec le rachat en 1998 de l’entité de métallisation sous vide et laquage MSV

2. L’INNOVATION comme fer de lance pour apporter des solutions uniques et qui s’adaptent aux

évolutions du marché comme :

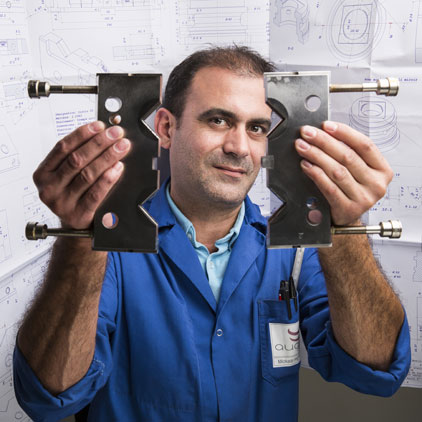

- COMP’STEEL solution de lestage simplifiée standardisée et automatisée

- READY TO PACK, process de développement standardisé pour diviser par

deux les temps techniques de mise sur le marché

3. L’AUTOMATISATION comme pilier d’amélioration et de maitrise des coûts et de la qualité totale

DEPUIS DES DECENIES AUGROS COSMETIC PACKAGING POURSUIT UN SEUL OBJECTIF

L’EXCELLENCE DU SERVICE RENDU A SES CLIENTS.

RÉALISATIONS ICONIQUES

RÉALISATIONS ICONIQUES

Des valeurs partagées

L'engagement

Auprès de nos clients, garantir une qualité totale dans le service rendu et les produits délivrés.

Auprès de nos collaborateurs, avec un management responsabilisant permettant à chacun d’évoluer.

Auprès de la région, pour faire perdurer le savoir-faire français et maintenir le bassin d’emploi.

Auprès de la société et des générations futures, avec le souci permanent de notre responsabilité sociale et environnementale (ENGAGEMENT RSE).

AVANCER ENSEMBLE VERS L’EXCELLENCE

Des valeurs partagées

L'esprit collectif

La fidélité, partagée avec nos clients et nos collaborateurs nous fait perdurer.

La confiance, de nos clients et de nos collaborateurs nous fait progresser.

La passion du métier, et l’exigence du meilleur nous lient jour après jour à nos collaborateurs et à nos clients.

REGARDER ENSEMBLE DANS LA MÊME DIRECTION, L’EXCELLENCE

Des valeurs partagées

L'esprit pionnier

Apporter des solutions innovantes et créatives.

Répondre avec les meilleures technologies disponibles.

Concevoir et développer des solutions d’emballage et des outillages, qui s’adaptent aux exigences de chaque demande.

AVOIR ENSEMBLE UN SEUL ET MEME OBJECTIF, L’EXCELLENCE

UNE ÉQUIPE ATTENTIVE ET PASSIONNÉE

Président du Directoire

Depuis 1991

Directrice Administrative et Financière

Depuis 2017

Directeur des Opérations

Depuis 2014

Responsable Qualité

Depuis 1999

Directrice Commercial et marketing

Depuis 2021

Responsable Commercial et Développement

Depuis 1994

Responsable Ordonnancement

Depuis 1996

Directeur Technique R&D pole Décor - MSV

Depuis 2021

Responsable Logistique

Depuis 2001

Responsable Administration des Ventes

Depuis 2005

Responsable Essais et Mise au Point

Depuis 2001

Responsable Industriel

Depuis 2014

Technicien Vernisseur

Depuis 2008

Technicien Méthode Production

Depuis 2004

Responsable Logistique

Depuis 1995

Responsable Outillages

Depuis 2014

Les chiffres clés

unités livrés en 2019

Les chiffres clés

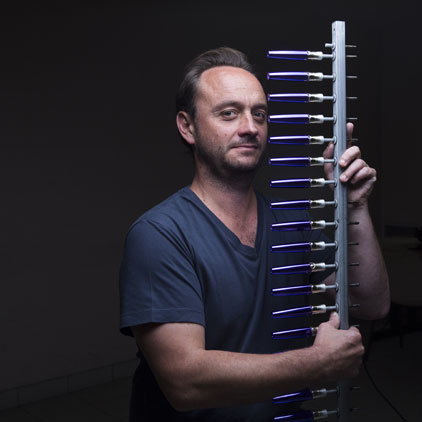

lignes de vernissage

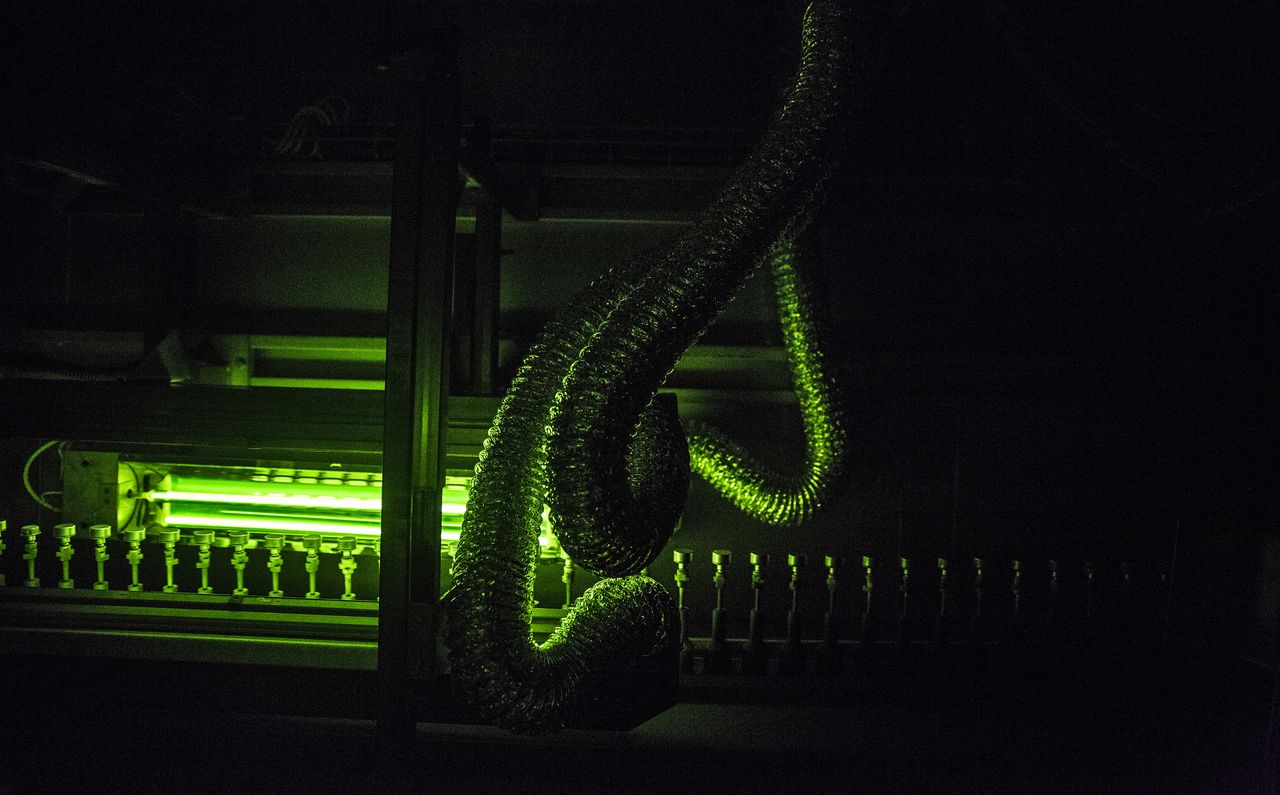

cloches de métallisation grande capacité

Les chiffres clés

robots 6 axes

presses à injecter de 80T à 400T

Les chiffres clés

collaborateurs

sites de production en France